Charge Air Cooler

The charge air cooler effectively cools the air after it has passed through the turbocharger on its way to the engine. The air with lower temperature is compressed to provide optimum power in the combustion chambers. This part has the same function as an intercooler, but for larger heavy duty applications.

- Precisely engineered cast-aluminum tanks for a perfect fit

- Built with premium grade materials to ensure product quality and durability

- Welded tube design to minimize pressure drop and maximizing heat dissipation in order to achieve maximum engine operating power

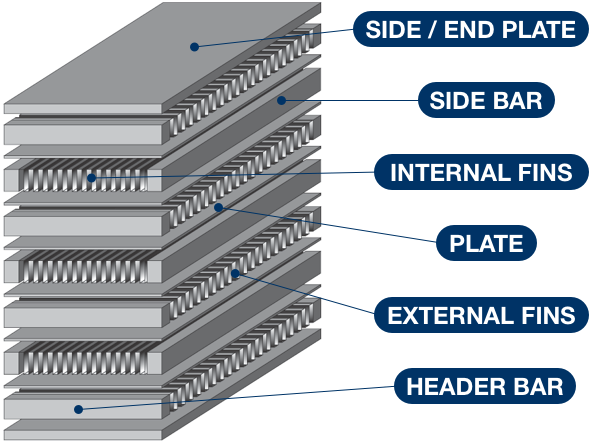

Components: tube & fin vs. bar & plate design

Tube and fin CACs are quite similar to radiators. They use seamless or extruded tubes with internal fins to maximize heat transfer and increase tube strength. External fins are then placed between the tubes and the resulting stack is fitted in the tank header just like a radiator. This type of CAC is the standard construction for most OEM productions and is designed to fit the manufacturers cooling requirements.

However, some applications are more demanding on the CAC unit and as such; premature failures have sometimes been observed on this design when used in conjunction with the heavier applications. Such failures can include cracking of the tubes at the header joints as a result of thermal fatigue from constant expansion and retraction of tubes. Therefore, for these more heavily demanding applications, the bar & plate design is usually a better option.

The bar & plate design consists of fins that are pressed together between aluminum sheets and fitted with header and face bars. This stacking of bars, plates, and fins, is then brazed together, creating a single, solid piece allowing tanks to be welded directly on the core. This type of construction results in much stronger solution for the more demanding applications since it can withstand higher pressures and temperatures.

Common Charge Air Cooler Failure Symptoms

- Loss of engine power

- Increased fuel consumption

- Exhaust manifold failure

- Premature piston, ring and valve failure

- Elevated coolant temperatures

- Turbocharger failure

- Increased particle levels in emissions

Common Causes of Failure

The charge air cooler is vulnerable to stress and overheating which translates into the separation of the top plate from the header plate, tube distortion or failure of the tube wall. Like other cooling system products, the aluminum core can become corroded, and the part can crack after a collision. Furthermore, turbocharger failure can result in a subsequent charge air cooler failure in a chain reaction.

In case of Charge Air Cooler failure, the engine won’t receive enough cool, dense air resulting in loss for complete combustion and exhaustion of unburned fuel.

Not replacing a failed charge air cooler can directly affect horsepower, fuel mileage and emissions.